Biogenic Silicates

Silicates From Rice Hull Ash (RHA)

Bio-Process Group is currently looking for a partner in implementing our technologies to convert rice hull ash, an agricultural waste product, into higher value products. Contact us for a more detailed proposal on the finances and specifications of the project.

Rice hulls, also called rice husks, are a low value by-product produced by rice millers on a daily basis. There are about 10 million tons of rice grown in the US, which is associated with about 2 million tons of rice hulls, over 50% of which is produced in Arkansas.

Silica makes up a large portion of the rice hull structure, about 16 - 20%, making rice hull ash a potential source of silica that is renewable and not dependent on mined resources. To tap into this potential, Bio-Process Group has developed a system to extract silica from rice hull ash and create renewable, higher value products from a low value by-product.

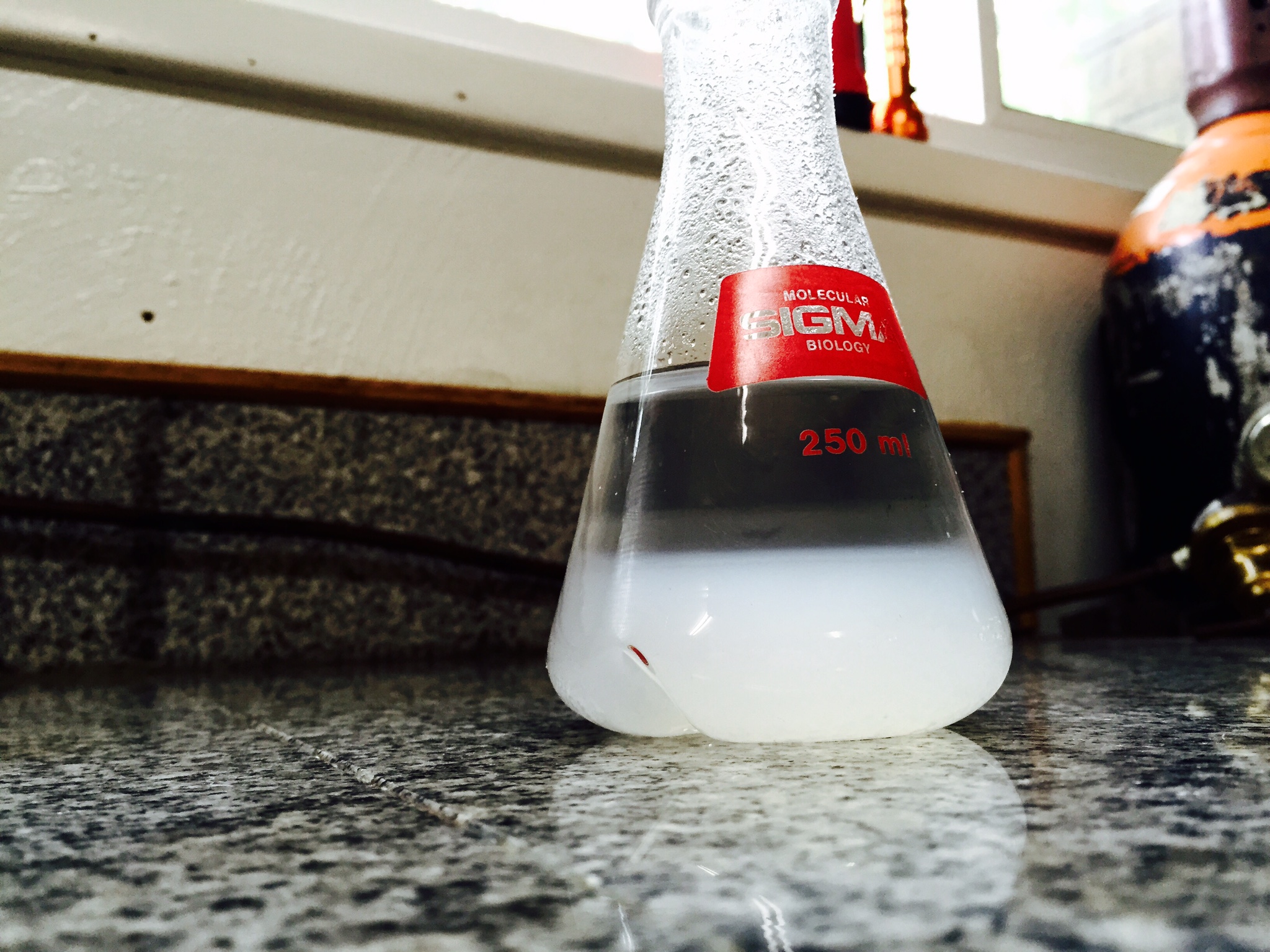

BPG has been developing and optimizing our RHA to silicate process over the last several years. We have determined yields and separation strategies for separating soluble sodium silicate from insoluble carbon and crystalline (insoluble) silica. We have done a thorough literature survey, followed by lab and pilot scale trials in our facilities. Our system ultimately yields three products: sodium silicate, potassium silicate, and activated carbon/silica pellets.

Sodium Silicate

Liquid sodium silicate has a wide variety of applications across several industries including soap and detergents, adhesives, drilling, wastewater treatment, and paper production. In 2022 MarketWatch estimated the global sodium silicate market to be worth $2.2 billion, with forecasted growth to $2.4 billion by 2028. Currently sodium silicate is almost entirely produced through a very high energy process and with a non-renewable mined resource (quartz sand) as the raw substrate. We believe there is a major opportunity to capture a portion of this market, creating value in three ways:

Offering an identical product at a lower price

Offering an identical product made from bio-renewable sources for companies looking to market their products with sustainability in mind

Offering a product with different levels of micro-contaminants allowing the lower cost production of ultra-pure solid silica for either solar cells or semi-conductor chips

Potassium Silicate

Potassium silicate is another product of this system with many applications, particularly in agriculture. It can be applied as a foliar spray or absorbed through the roots of crops, strengthening the plant structure and increasing resistance to disease and pests, increasing yields.

Sponsored Project: Silica Gel From Sugar Cane Bagasse

Bio-Process Group is proud to have partnered with Amyris in the development of Biosilica™, renewable, biogenic silica gel derived from sugar cane bagasse ashes.